WELCOME

I am a proactive problem solver and

first-principle based thinker.

My mission is to enable new product development by asking the right questions early on,

and to empower the creation of defect free, user-friendly functionality that can easily scale.

I am a proactive problem solver and first-principle based thinker.

My mission is to enable new product development by asking the right questions early on,

and to empower the creation of defect free, user-friendly functionality that can easily scale.

A.S. (Engineering)

2003 - 2006

Completed all lower division coursework

at a commnunity college while working full time.

Frequently held best grades in engineering courses.

B.S. Applied Physics

2006 - 2009*

Frequently ranked among the top ten public universities in the nation.

Concentrations: Electrical Engineering | Mechanical Engineering

Senior Thesis: Closed Loop Control Systems

* Qualified to walk in 2009 UCI commencement ceremony

Entered workforce during recession | Prioritized gaining experience

Completed remaining two courses in subsequent years

“The more I learn, the more I realize how much I don't know.” - Albert Einstein

EDUCATION

College is where I learned how to learn.

Passing courses like quantum physics and statistical thermodynamics gave me the confidence that I can learn anything.

Choosing applied physics showed me the balance required between theoretical and real-world application.

Related Coursework

Single-Variable Calculus | Multi-Variable Calculus | Linear Algebra | Differential Equations | Statistics

Newtonian Physics | Quantum Mechanics | Relativity | Statistical Thermodynamics | Electromagnetic Theory

Materials Science | Fluid Dynamics | Programming | Electronics | Circuit Analysis | Machine Theory | Control Systems | Robotics

Statics | Dynamics | Machine Shop | Welding | Computer Aided Drafting | Chemistry

* Qualified to walk in 2009 UCI commencement ceremony | Entered workforce during recession | Prioritized gaining experience

Completed remaining two courses in subsequent years

EXPERIENCE

14 Years Experience | Deployments to 6 Continents | Billions of $ of Equipment Controlled | Decades of Incident Free Runtime

2009 - 2023

TechnipFMC | UCOS Controls & Automation

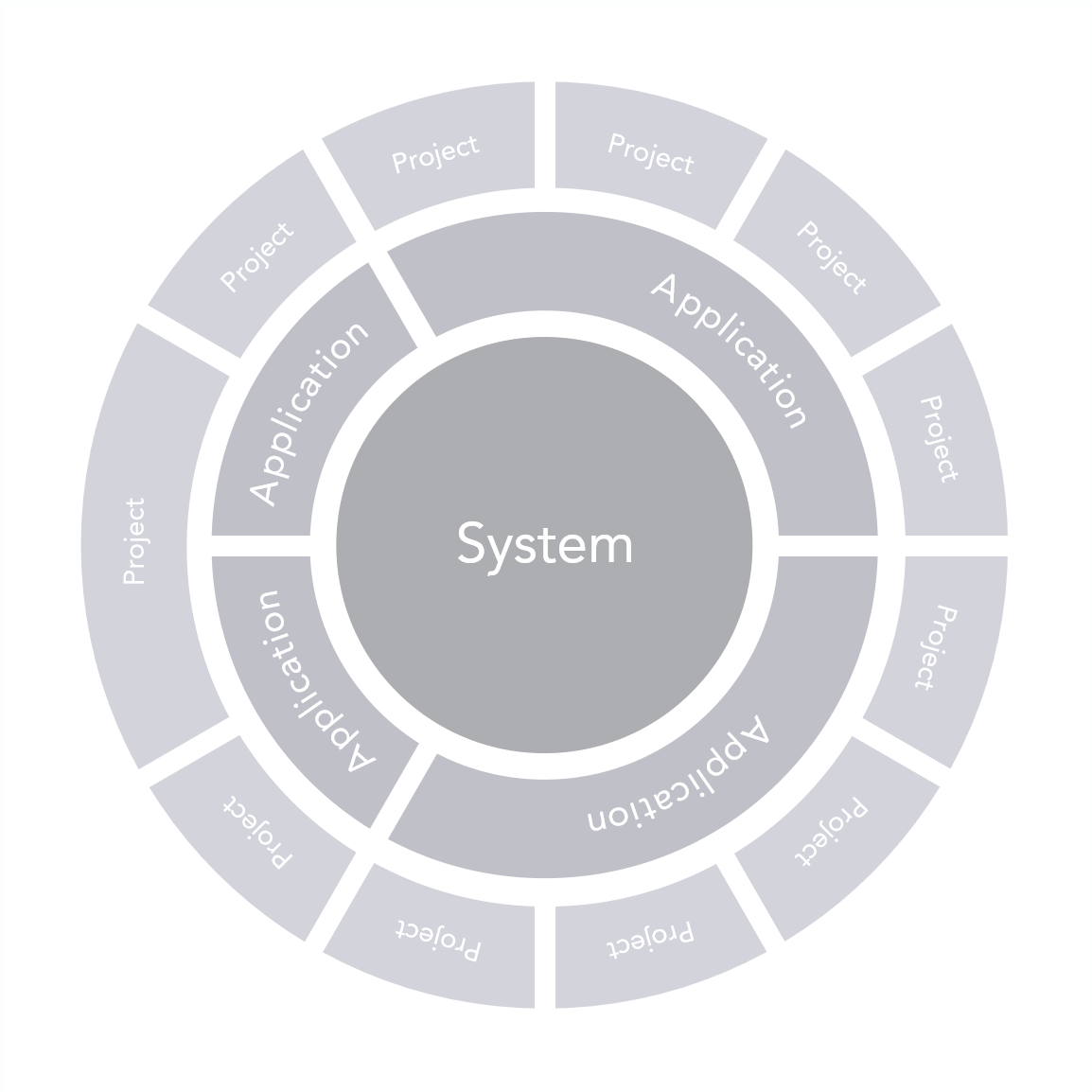

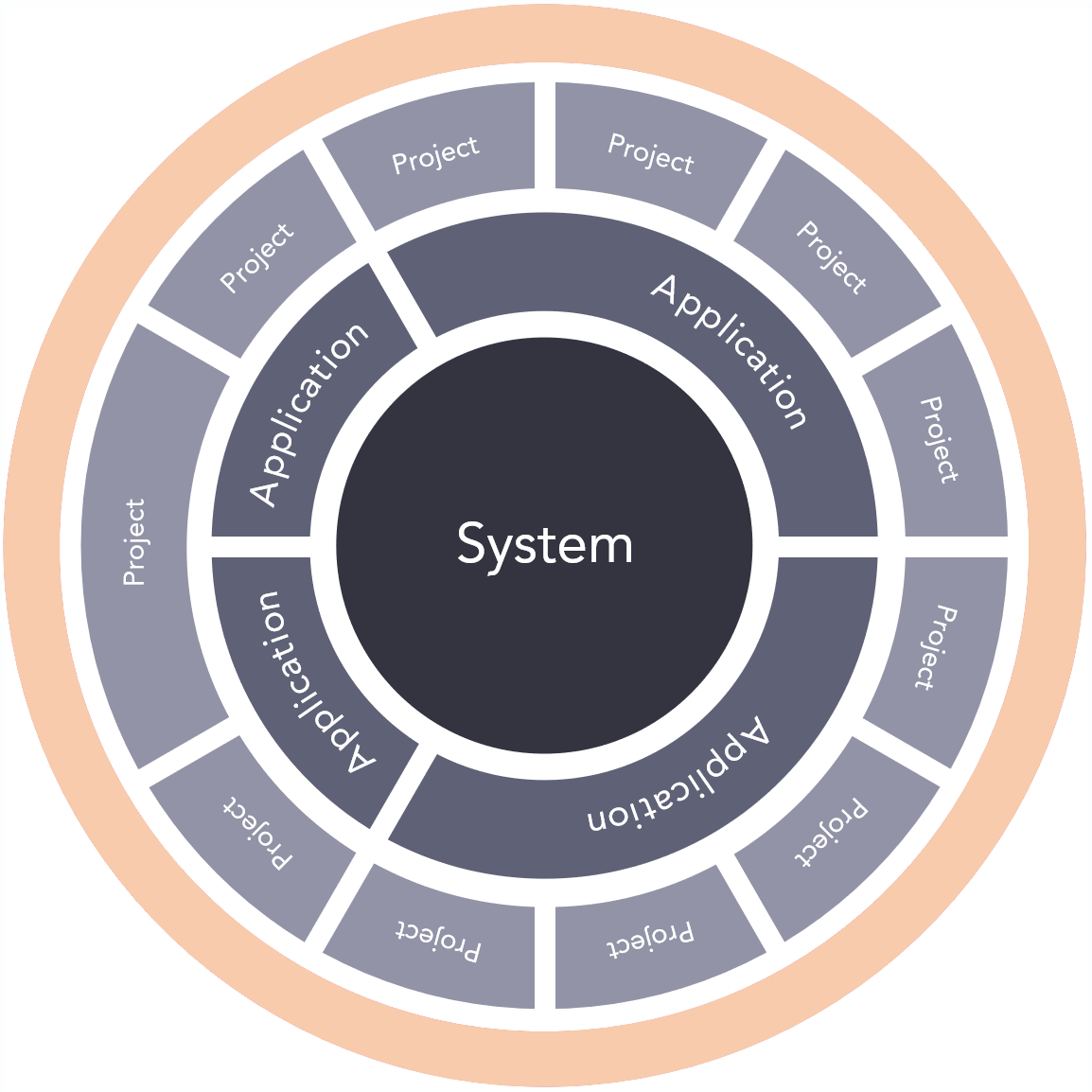

TechnipFMC is a global leader in the energy industry with over 20,000 employees. UCOS (User Configurable Open System) is TechnipFMC's software based controls platform.

After hiring on at Control Systems International in 2009, I played a vital role in our acquisition by FMC Technologies in 2012, which then merged with Technip in 2017 to form TechnipFMC.

During my tenure at TechnipFMC, I have been the proud creator/originator of many high stakes automation & control applications. Lately, I find that I add the most value by enabling others.

Controls

Engineer

2009 - 2012

Applications

Manager

2012 - 2016

Product

Responsible Engineer

2016 - 2021

Senior

Systems Engineer

2021 - 2023

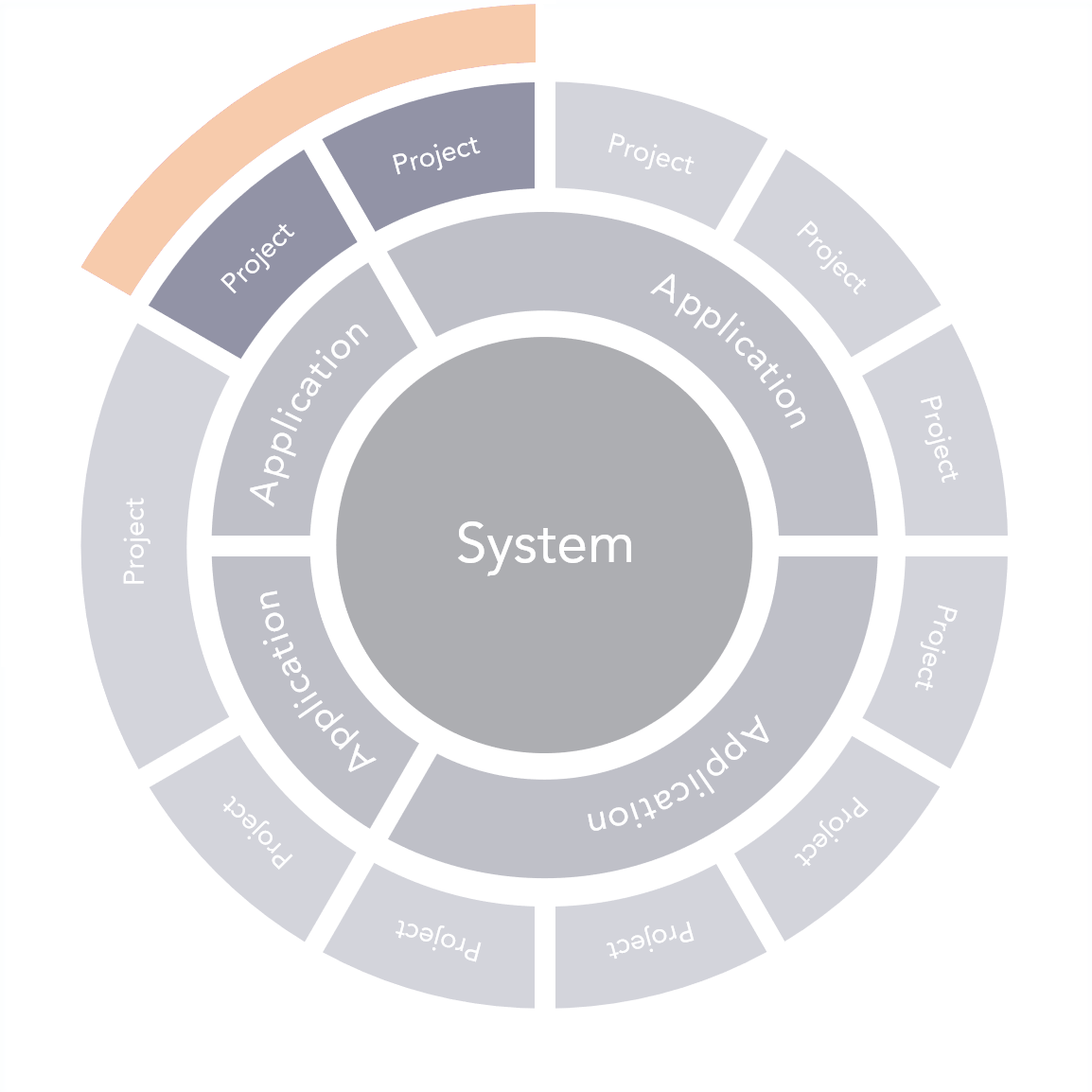

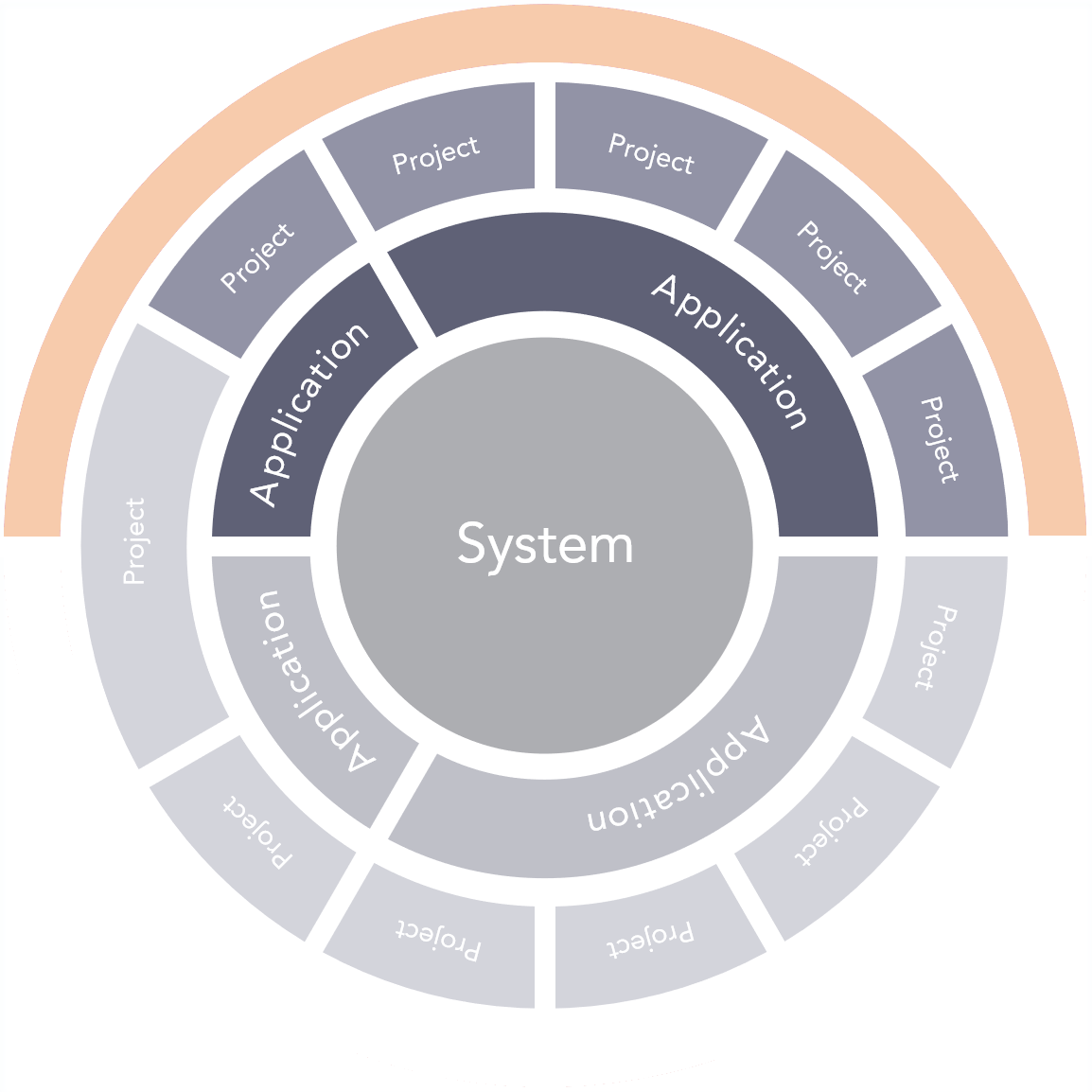

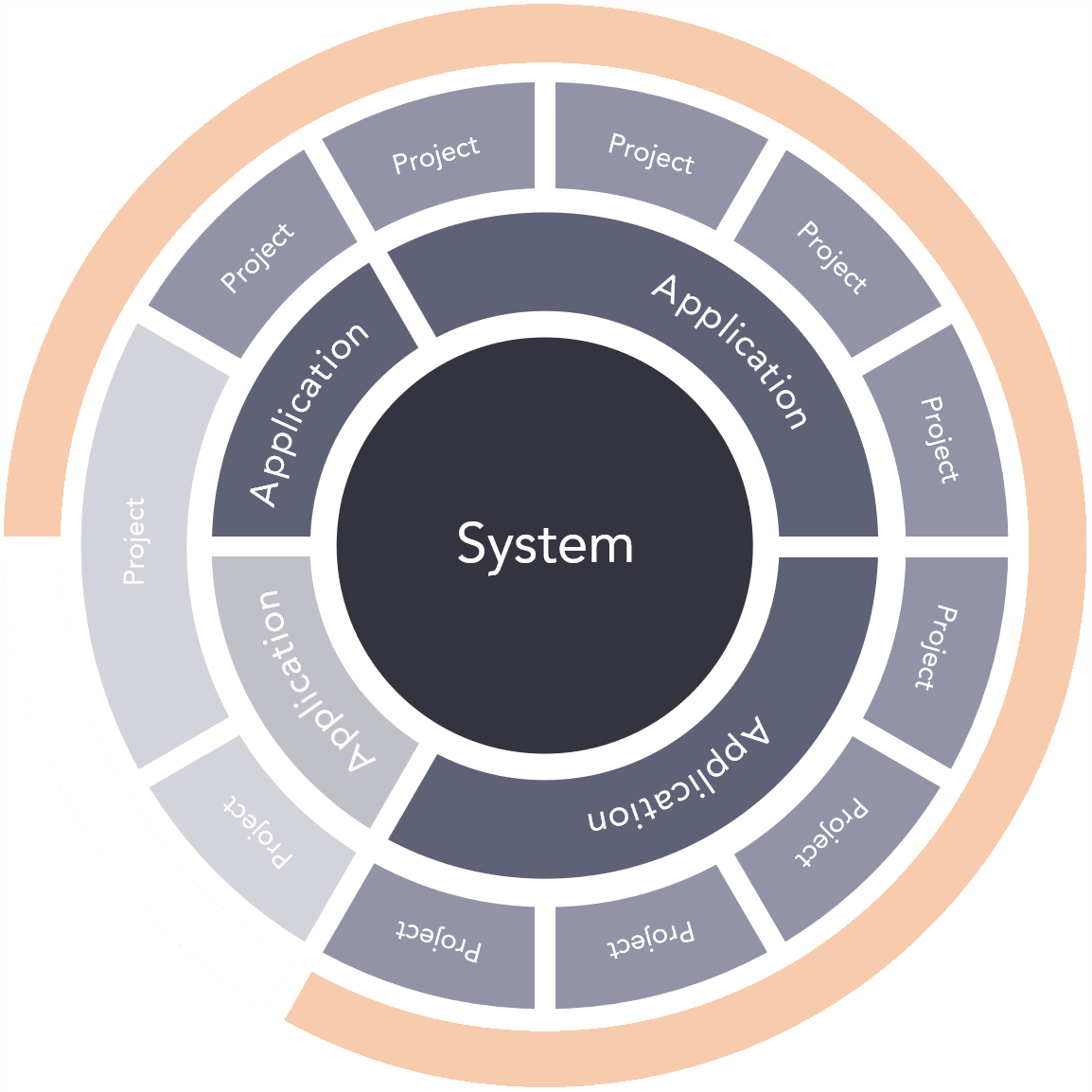

Role | Scope | Job Description

Enabling latest generation of engineers by sharing hard-learned best practices.

Standardized applications enable engineer based configure to order projects.

One-off control system projects based solely on customer specific requirements.

Integrated systems configured during runtime by unspecialized technicians.

Hover over a role above to see more about it's related scope and job description.

-

Lead in the creation of algorithm based user-friendly, real-time, fault-tolerant, embedded control systems for the energy industry.

-

Collaborate with a team of programmers to advance the functionality within a proprietary software based controls platform.

-

Define and execute fomal test procedures at all levels including software, hardware, unit, system, and integration.

-

Globally standardize and package funcitonality into applications that enable configure-to-order project deployments.

-

Lead a team and create an environment of collaboration, professionalism, and excellence (mission statement).

-

Take solutions from concept to commissioning using self created milestone based execution plans.

-

Assist in the definition of software architectures and development tools that positively impact engineer productivity.

-

Lead innovation strategy to ensure systems can easily scale and be configured during runtime by unspecialized technicians.

-

Mentor engineers in best practices on various topics including customer experience, reliability, safety, and per-deployment cost reduction.

-

Be globally responsible for complex products comprised of hardware, software and configurations.

-

Collaborate with a team of engineers to develop and seamlessly integrate various applications.

-

Collaborate with product managers and field service technicians to enable successful deployments.

TechnipFMC is a global leader in the energy industry with over 20,000 employees.

UCOS (User Configurable Open System) is TechnipFMC's software based controls platform.

After hiring on at Control Systems International in 2009, I played a vital role in our acquisition

by FMC Technologies in 2012, which then merged with Technip in 2017 to form TechnipFMC.

During my tenure at TechnipFMC, I have been the proud creator/originator of many high stakes automation & control applications. Lately, I find that I add the most value by enabling others.

PROJECTS

“A mind is like a parachute. It doesn't work if it is not open.” - Frank Zappa

Increased

Safety

Less Redzone Operations

Reduced

Operator Mistakes

$1,000,000+ per wireline cut

Reduced

Operational Costs

30+%

Increased

Customer Satisfaction

Safe | Reliable | Savings

Generated

Sales

$10,000,000+

Application Creator

Frac Pad Automation (CyberFrac)

CyberFrac is the intelligence backbone of TechnipFMC's iComplete system.

It automates the hydraulic fracturing process, reduces the transition time between

standby > wireline > frac phases, and helps to prevent cutting wireline.

The application monitors and controls hydraulic accumulators and valves.

It uses intrinsically safe balance stem monitors installed within the red zone for

valve position feedback and enforces valve interlocks based on critical data

including availble hydraulic pressure, fluid level and active tree phase.

Personally designed/assembled/wired original control panels, developed original

controls database and presented to TFMC Board of Directors/CEO.

Created and executed test procedures, generated operation manuals.

Led the original field trials with Chevron at a live site in the Permian Basin.

Developed runtime configruable one-click phase transition valve sequencer.

Increased

Professionalism

Formal Documentation

Reduced

Operational Costs

Configure to Order

Increased

Customer Satisfaction

Quality | Ease of Use

Generated

Sales

Most Profitable App.

Application Creator | Global Standardization Lead

Master Control Station (MCS)

The UCOS MCS application monitors & controls subsea fields consisting of

trees (well heads) and manifolds residing on the seabed. Each tree is rated for

pressures up to 15,000 psi, temperatures up to 400 F and depths to 10,000 ft.

A single field capable of producing $ millions in hydrocarbons per day.

Application includes monitoring/control of Hydraulic Power Units (HPU),

subsea power & communications, downhole sleeve valves, downhole

interface (DHI) cards, discrete valves, step actuated chokes, e-actuators, etc.

Includes redundancy, Graphical User Interface (GUI), user managment,

alarm management, historical data storage, reporting, trending, interlocks,

emergency shutdown sequencing and valve signatures.

Lead/only UCOS engineer for pre-salt projects ($1.5B contract | 100+ trees)

Innovative

Solution

Simplifies Complex Operations

Increased

Customer Satisfaction

Quality | Ease of Use

Generated

Sales

Most Profitable UCOS App.

Functionality Creator

Multi-Phase Pump Control (MPP)

The UCOS MPP functionality monitors & controls two

helico-axial 2 MegaWatt pump modules that reside on the seabed.

Each pump is capable of providing 7,500 psi in artificial lift.

Cascade Proportional Integral Derivative (PID) control is used to optimize performance

while also enabling minimum flow protection, torque control and load sharing.

Application includes PT/TT monitoring, VFD control, recirculation line choke control,

and discrete valve control.

Pumps are started and stopped using a carefully prescribed sequence.

The industrial fault tolerant controller works to keep each pump operating within

a dynamic 3D operational envelope whose boundaries are defined by the live

gas-to-liquid ratio and pump suction/discharge pressures.

Functionality Creator

MCS to DCS Interface Standardization

MCS to DCS Interface Standardization (MDIS) is a collaboration between all major

energy companies to standardize the interface between an MCS, which monitors &

controls subsea equipment, and the topside rig control system (referred to as the DCS).

As the lead UCOS engineer, I served on the global MDIS panel, enabled a succesful

interoperability test between all DCS vendors. I also developed the first ever

MDIS deployment database for Statoil/Equinor, which included comprehensive

design specifications, test procedures, and customer witnessed acceptance tests.

The UCOS MDIS functionality utilizes OPC UA and well designed logic

to enable full monitoring/control from the DCS while severely reducing both

the required integration time and probability of configuration errors.

Industry

Leading

First Ever Deployed System

Reduced

Integration Time

Template Based Configuration

Improved

Quality

Type Based Point Configurations

Functionality Creator

Lease Automated Custody Transfer (LACT)

A LACT enables custody transfer between an upstream producer and the

midstream oil/gas company responsible for storage and transportation.

It is essentially a sales pump with ability to reject non-merchantable product.

Personally developed controls database, test procedures, operation manuals.

Conducted first customer witnessed FAT (SKID included) with Shell.

As the first fully runtime configruable UCOS application, it monitors and controls pumps,

basic sedementation & water meters, sample pots, diverter valves and flow meters.

It will automatically switch product from a sales line to a reject line if it is deemed

unmerchantable and uses a software based flow computer to apply a meter factor and

pressure/temperature compensation to define the API gross standard volume (GSV).

It also generates a ticket which acts as a Bill Of Latency (BOL).

Innovative

Solution

First Ever Runtime Configurable

Reduced

Lead Time

User Definable P&ID | Cause & Effect

Improved

Quality

Test Once | Deploy Many

Project Creator

PMM Test Bed Automation

A Permanent Magnetic Motor (PMM) has many advantages due to its

windings around the fixed stator instead of the moving/brushed rotor.

The FMC Technologies PMM test bed was essentially a dynomometer

used to qualify large 2MW motors slated for offshore oil/gas production.

The same motors were later used/controlled in the UCOS MPP application.

As the only automation engineer assigned to the project, I worked side by side

with the facility operators, collected and generated requirements, developed,

tested, commissioned and supported project.

Project included monitoring and control of transformers, 3 Phase Siemens VFD,

induction motors, gear boxes, torque meters, cooling systems, vibrations,

fire suppression, load banks and the bearings/end turns/stator of the PMM itself.

Cause & effect logic was used to enabled safe testing and data collection.

Project Advisor

Emissions Control (eMiss)

"E-Mission™ utilizes process automation, wireless instrumentation and

machine learning to monitor and control vapor pressure in real-time.

By re-evaluating how and where we want to apply or remove heat, and lower

pressure, we can maximize oil production and minimize greenhouse gas

emissions based on the changing conditions of the well and weather." - TechnipFMC

I served as a project advisor and worked to support the UCOS application.

I worked side by side with related project engineers to shed light on best practices

that enable quality functionality that is both runtime configurable and scalable.

Participant Engineer

Next Generation Automation (NGA)

Proud to have been selected to contribute to TechnipFMC's

global Next Generation Automation initiative.

Allthough UCOS ultimately was not selected to be used.

Many trips to Norway for collaboration workshops.

Wrote my own SPI driver to control stepper motors and

developed/presented prototype subsea valve control system.

Many More...

-

Intervention & Workover Control System (IWOCS)

-

Field Recorder Product Responsible Engineer (PRE)

-

Flow Research and Test Center Automation (FTRC)

-

United States Bureau of Reclimation (USBR) Dasalting Plant

-

Multi-Phase Flow Meter (MPFM)

-

Advanced Oil Stabilization (AOS)

-

Modular Automated Processing System (MAPS)

-

Tank Level Monitoring (TLM)

-

Terminal Automation Modernization

-

Alaska Pipeline

-

Drinking and Waste-Water Treatment (City of Phoenix)

-

Natural Gas Compression & Distribution

As a physics major practicing engineering, I believe in first principle based solutions where good design is combined with engineering.

I work best on a team where members complement each other and prioritize advancing the art over just advancing their own careers.

I thrive under pressure and have learned to use my OCD tendencies as an advantage. To me"good enough" is never good enough.

Jan 2023 - Current

CrossnoKaye | Senior Technical Product Manager

EXPERIENCE (continued)

TESTIMONIALS

2021 Driving Change Award Recipient

iComplete | Innovative Approach & Solution

TechnipFMC company wide award

I worked with Brad in a newly created team to spearhead global standardization on subsea production system app called Master Control Station (MCS) very early in my career. As I leave the company almost 8 years later, there is no doubt that Brad was and continues to be one of the best things our team had to offer.

Brad was my first manager as a full-time employee, and I regard him as an unofficial mentor in many ways. Not only did he teach me Industrial Control principles, but he also showed me how to keep a team motivated and engaged.

On the technical side, Brad has an incredible eye for detail; he went into every nook and cranny of our control system platform UCOS to uncover efficiencies and propose solutions to urgent issues. He was the first one to submit bug reports with videos edited with annotations and narration to developers, which inspired me and others to do the same. He distills a lot of technical info into animated engaging presentations to his peers and upper management. He is very resourceful, finding and learning to use third party tools to compliment in-house software when needed many times. He also had a clean record for on-time delivery.

On the leadership side, he sat down with the team and worked to get a mission statement that I still remember today. Before then, I thought mission statements were cheesy, but he showed me how to do that the right way to do it. I came to work motivated every week because Brad was able to distill our purpose and take us with him in the process. He always supported my career growth and always made sure I was doing something that I find interesting and aligned with my personal goals. A couple of times he organized all-hand meetings for me to showcase my beta projects to the rest of the team which was great! I think his combination of caring, supportive, sincere, and clear guidance attributes makes him one of a handful truly outstanding leaders I’ve met, even after so many years.

"There is no doubt that Brad was and continues to be one of the best things our team had to offer...

Brad was my first manager as a full-time employee and I regard him as an unofficial mentor in many ways.

Not only did he teach me Industrial Control principles but he also showed me

how to keep a team motivated and engaged."

Carlos Cordova Alvarez, CA

""

Thiago Machado | Lead Pressure Pumping Engineer | TechnipFMC

Nathaniel Ramsey | Field Operations Manager | TechnipFMC

"I have witnessed Brad put in tremendous effort and commitment

to making the Chevron Automated Frac Pad field trial successful.

He has been a great partner for the Surface business...

and without his dedication the field trial would not be possible."

TechnipFMC Elevating Excellence Award

Sobitha Gunatilleke | UCOS Surface Operations Manager | TechnipFMC

"Excellent job at the Board of Directors presentations in San Antonio.

It was a short timeline given the setup that had to be completed

with multiple Surface applications. Appreciate the extra effort for the demo

while advancing the automation programming within the applications."

TechnipFMC Elevating Excellence Award

"I have had the pleasure of working with Brad in various contexts.

His commitment, technical skills and positive attitude were my first impression about him.

Brad was always open for new ideas and to discuss technical solution

and also for providing feedback after evaluation and tests...

I learned a lot with him and I`m extremely grateful for that experience."

Bruna Santos | UCOS Subsea Manager | TechnipFMC

I have had the pleasure of working with Brad in various contexts. First time I met Brad was in 2012 when our companies merged and I was his internal client. Our first project together was huge - full package comprised of $1.5 billion in labor and equipment - and there was a great level of complexity, volume and development ongoing. His commitment, technical skills and positive attitude were my first impression about him. Brad was always open for new ideas and to discuss technical solution and also for providing feedback after evaluation and tests. I learned a lot with him and I`m extremely grateful for that experience. We were able to deliver the project on time and on budget and we together achieved a great milestone to install all Subsea automation on Petrobras Pre Salt Fields and define an important standard for the main and biggest Oil and Gas operator in Latin America. That was only possible because we established an efficient communication flow, great level of trust and sense of belonging to ONE single team. I`ll never forget this experience and Brad was a key person responsible for this huge achievement.

Jeff Whitmore | Director of UCOS Controls & Automation | TechnipFMC

"As a constant high performer, its challenging to single out activities that set you apart from your peers.

However, your recent '11th-Hour' heroics where you diligentlyworked through the weekend

to apply the input configuration to avoid liquidated damages is a shinning example!"

TechnipFMC Elevating Excellence Award

I had the fortune of working with Brad shortly after joining the Surface Digital Product Management team and faced the daunting task of learning a new control system as well as the Upstream Production Industry. Brad is one of those individuals with the rare trait of being able to seamlessly shift from discussing big picture strategic vision, road map, end goal to the level of minute detail required for code and logic development. Working with someone with his knowledge of Physics, control logic methodology, and intimate knowledge of advising the Core Product teams development through multiple generations of a control system was a singular experience for me, in over 15 years working in automation.

I cannot sufficiently stress the strategic advantage of someone who can operate simultaneously in blue-sky ideation and the nuanced detail of code development (where were going and how to get there). It was impressive to work with Brad, weaving the art of the possible while keeping us grounded through his understanding of time and resource demands each decision point placed on the projects. Brad is the quintessential renaissance man: ingenious, thorough, a selfless teammate and teacher.

"I had the fortune of working with Brad shortly after joining the Surface Digital Product Management...

Brad is one of those individuals with the rare trait of being able to seamlessly shift from discussing big picture

strategic vision, road map, end goal to the level of minute detail required for code and logic development.

Working with someone with his knowledge of Physics, control logic methodology...

was a singular experience for me, in over 15 years working in automation."

Collin Gallagher | Surface Digital & Controls Product Manager | TechnipFMC

"Brad proactively reached out and offered his knowledge and experience as a mentor.

Brad actively engaged with young engineers and helped them

expand their knowledge of controls and software engineering.

This included detailed training and hands-on support."

Arthur Weiner, CA

I worked with Brad when I joined the UCOS Surface Operations team at TechnipFMC. Brad proactively reached out and offered his knowledge and experience as a mentor. Brad actively engaged with young engineers and helped them expand their knowledge of controls and software engineering. This included detailed training and hands-on support in PID control theory and tuning strategies, quantitative analysis of complex valve and actuator operations and strategy, and implementation for protective responses to potential process hazards.

"In 26 years of my career with TechnipFMC I have met many smart engineers.

Brad Deemer was the special one --- the brightest engineer I have worked with..."

Emir Kapic | Senior Software Engineer | UCOS Product Development

In 26 years of my career with TechnipFMC I have met many smart engineers.

Brad Deemer was the special one... the brightest engineer I have worked with.

What separates Brad from the rest was his ability not only to create state of the art UCOS and HMI projects but help me as a developer by actively communicating his own analysis while working on UCOS; he identified and suggested numerous features in UCOS that needed improvement. Brad also created myriad of tools utilizing best practices for the rest of the team to improve efficiency and product delivery.

HOBBIES

Hover over any image to read more about it.

CONTACT

Controls & Automation

Mastery

Supervisory Control & Data Acquisition (SCADA) | Distributed Control System (DCS)

Communication Protocols | Modbus | Profibus | CANBus | ProfiNet | EtherIP | OPC

Boolean Based Logic Control Schemes | Programmable Logic Controllers (PLC)

Cause & Effects | Interlocks | Permissives | Sequencing | P&IDs | IO Lists

Intuitive Graphical User Interface (GUI) Development | User Management | Privileges

Historical Data Storage | Reporting | Trending | Alarm Generation & Management

Proportional Integral Derivative (PID) Control | Tuning | Feedback Mechanisms

Safety (SIL) | Reliability | Redundancy | Voting | Fail Safe Enablement | Asset Integrity

Process Optimization | Machine Learning | Automated Testing

State Engines | Operational Modes | Retentive Setpoints | Look Up Tables

VFD Control | Duty Cycling | Valve Signatures | Hydraulics | Pneumatics

Metering (PD/DP/Ultrasonic/Coriolis/Turbine/etc) | Instrumentation | Sensors

Custody Transfer | Flow Computer Design | Ticketing | API Standards

Industrial Panel Design | Wiring | Termination | Hardware Troubleshooting

NEMA Standards | Ingress Protection (IP) | Mimic Panel Design

Emergency Shutdown (ESD) | Hierarchy | Execution Philosophies | Trip Conditions

Hazardous Area Classifications (CxDy) | Intrinsically Safe Hardware Design

Survival Training | Helicopter | Offshore | FracPad | Fire | Escape | Site Certifications

Product & Engineer Development

Expert

Product Management

Estimation | Gap Analysis | Scope Definition | Strategy | Design | Development

Testing | Field Trials | Deployment | Maintenance | Support | Defects | Features

Agile (new product development) | Waterfall (established product deployment)

Sales & Marketing

Board of Directors/CEO Level Presentations | Customer Sales Presentations

Training

Engineer Development & Training | YouTube Based Training Videos

Documentation

Design Specifications | Control Narratives | Test Procedures

Reports | Release Notes | Operation Manuals | Fast Facts

Fundamentals

Mastery of Microsoft Office tools including Excel, PowerPoint, Visio, Word, Teams

Wheelhouse

Capable of scaling an established product.

Best suited for new product development and enabling fellow engineer success.

Computer Sciences

Expert

Requirement Definition | Feature Requests & Prioritization | Defect Reports

Quality Control | Version Contol | Configuration Management | Interoperability

Backwards Capability | Installed Base Management | Software Roadmaps

Intermediate

Software Design & Development | Software Architectures

Object Oriented Programming | Relational Databases | Structured Query Language (SQL)

Open Database Connectivity (ODBC) | Computer Networking | OSI Model

Domain Controllers | DHCP Servers | Domain Name System (DNS)

Network Time Protocol (NTP) | IPs | Ports | Gateways | Subnets | UDP | TCP

Local / Wide Area Networks (LAN/WAN) | Virtual LANs | Network Troubleshooting

Network Security | Firewalls | Routers | Switches | Bridges | Repeaters

Windows | Linux | Command Line | Terminal Services | Remote Desktop Protocol

Programming (C/C#/C++) | Scripting

Security | Encryption | Zlib Data Compression | Store & Forward

Virtualization | Kubernetes | Containerization

SKILLS

“Without knowledge action is useless, and knowledge without action is futile.” - Abu Bakr

I believe that skills (the ability to do something) are earned, and that true knowledge is best demonstrated, not explained.

Therefore, I adhere to the "learn by doing" philosophy where you continually develop your own skills by making, but not repeating, mistakes.

ABOUT ME

Looking back now, I know I was always meant to be an engineer.

I was born with an innate curiosity... one that that led me to disassemble

all of my toys to see how they worked (sorry mom and dad).

Growing up, I was lucky to have a dad and grandpa who seemed to know how to do it all.

They gave me the confidence to try anything, embrace the failures, and push on.

Over the past decade I have discovered that the most innovative products are created

when open minded engineers and leaders collaborate in a people centered environment...

one where excellence is the main focus and continuous growth is always promoted.

While I am tremendously proud of the work I have done thus far in my career,

I am confident that my best work is yet to come.

More than anything, I am looking to work on a high performing team while

contributing to something bigger than myself!

Outside of work, I enjoy spending time with my wife, son and two dogs.

I also like creating personal projects, traveling, and any activity outdoors.

"Ever tried. Ever failed. No matter. Try again. Fail again. Fail Better."

Samuel Beckett

Customers Served

View on tablet or desktop to see all project challenges, actions and results.